In this two part tech talk series, we’re going to talk about our HD mid-wave products. We call all of our cooled products Ventus or Ventus HD for our high definition products with a 1280 pixel wide field of view.

Part one of this series will be about the sensors in the Ventus HD family of cameras. Part two we’ll have another tech talk describing all the optics designed specifically for the sensor and the approach we take to solve customers problems with integrated cameras as a components.

HexaBlu® is designed and built by DRS Infrared.

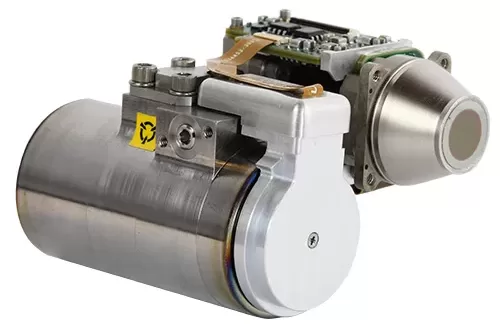

The sensor behind the Ventus HD is the HexaBlu®. DRS Infrared is an established American manufacturer of mid-wave technology well known in the Mercury Cadmium Telluride (MTC) business, and they’re unquestioned in the quality of coolers that they develop for these systems. They’ve been working on the HexaBlu® sensor for four years. It is a 1280 x 960 pixel array with 6 micron infrared focal plane. The 6 micron sensor is the first commercially available and actually deliverable small mid-wave pixel. The sensor is based upon DRS’s (HDVIP) Technology which stands for High Density, Vertically Integrated Photodetector which we will go into more detail about later in the blog.

Delving into more detail, this sensor supports fast frame rates up to 120 hertz. The integration mode is integrate while read (IWR) to reduce latency and enhance the user experience. It’s a high operating temperature (HOT) mid-wave sensor. This HOT mid-wave sensor actually operates at 140° kelvin, very high sensitivity. It has very high quantum efficiency(QE). Another critical aspect is its deep well depth. While the pixel size is only 6 microns, the well depth in a single integration is 4.8 million electrons. That’s unmatched in the industry. That’s especially important for background limited performance in mid-wave imaging.

The Ideal 6 Micron Sensor

I mentioned what the HDVIP detector material does, and this is a graph of the modeled ideal detector. You can see on the graph the solid black line is the ideal 6 micron sensor. The dotted blue line is what we would expect with the HDVIP architecture and the pixel spacing and the collection region of the diodes. The orange triangles are the actual measured results. What we see is that the measured results are almost overlaying the ideal HDVIP detector. This is an excellent MTF performance at the sensor.

In addition, we wanted to touch on some of the features of the electronics. The electronics are very efficient and very powerful. There’s a non uniformity and bad pixel replacement algorithm on board. The digital output is LVDS, 14 bits, and you have a UART to control everything and very efficient power supplies. You need 5 volts for the electronics and 14 volts for the cooler and that’s it, so it’s very efficient. We make HexaBlu® even simpler to use when we put it into a Ventus HD. We’ll talk about that in part 2 of these tech talks.

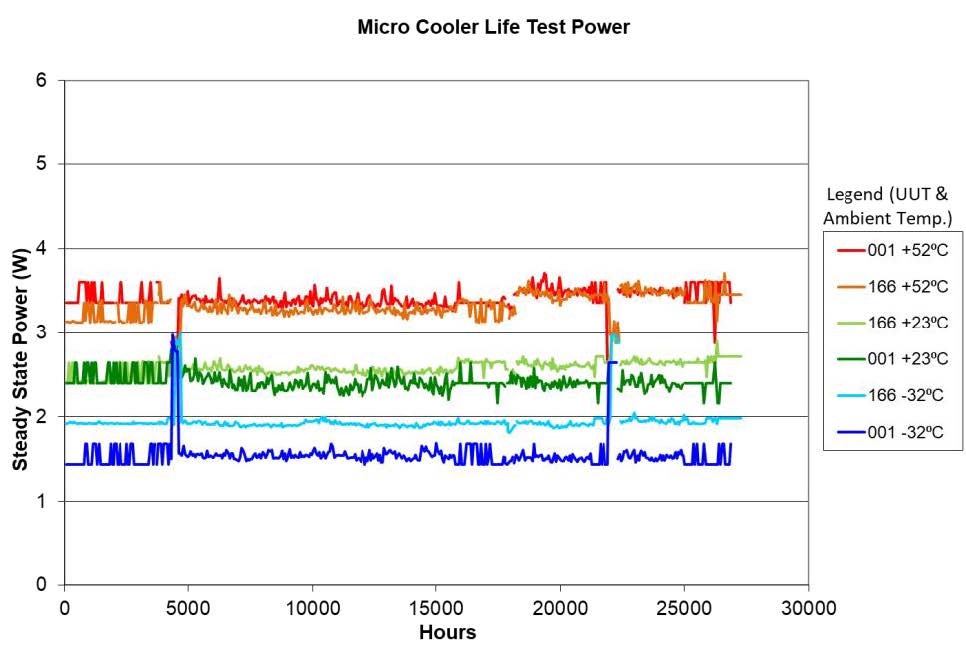

We also want to emphasize the cooler life of the HexaBlu®

If you’ve been in the infrared business, you know that the greatest strain on a cooler is the cool down cycle going from ambient temperature to the operating temperature, 300° kelvin and back to 140° kelvin. In the lifetime burn cycle that DRS puts these through, there’s three power cycles per 72 hour diurnal cycle and with cold, intermediate and hot stages. These coolers have been through three years of daily power cycles, daily temperature cycles, and again, no indication of deterioration. Having coolers operate under these conditions for three, four years is an amazing accomplishment. No other cooler publishes data like this. No other manufacturer publishes data like this. This is all available from us in published documents. Nothing can match the proven long life of the DRS HexaBlu®

We originally looked at the HexaBlu® for the drive sensor of Ventus HD because of the 6 micron pixel pitch. We’ve always believed in smaller pixels. Smaller pixels deliver a lot of range performance. Next, there’s no disputing the cooler life issue. We have customers that tell us all the time we need better cooler life and HexaBlu® delivers. Everything about the product is the top of the industry and what we believe is that we combine the best sensors and the best optics to create the best system.