Last modified on April 24th, 2024 at 7:44 pm

The Energy Drone and Robotics Coalition gave Sierra-Olympia’s VP of Sales, Jeff Leake, the opportunity to talk about methane and hydrocarbon strategies and applications for detection and visualization of gases. This will cover real world applications for methane and hydrocarbon emissions and compliance as it relates to handheld portable OGI cameras, OGI cameras for crewed or uncrewed systems, manned unmanned or drones. Also, OGI cameras for ground robot and then finally, optical gas imaging for fixed mounted continuous monitoring.

Methane and Hydrocarbon Emission Compliance

The current OOOOa standard has been in place for a number of years. That OGI standard, 60 g/hr with a 50/50 mixture of methane and propane gasses. Roughly 10,000 ppm. using a quarter inch orifice. The new proposed rules OOOOb and OOOOc are looking to target 19 g/hr for methane and 29 g/hr for butane at a distance of two meters away, also at a deltaT of around 5° centigrade at 1 meter/second. Methane “Super Emitters” are detected at 100 kg/hr and must be fixed within 10 days of being identified.

(Edit: This blog has been updated since originally posted to reflect the updated proposed rules.)

The new proposed standard that will go into place has been established by the United Nations and GMP and is being adopted by the rest of the world. One of the things that Sierra-Olympia has been working on is evaluating and making sure that our cameras will be able to meet these new rules. As a manufacturer, we’re jumping out in front and making sure that we’re compliant to the new standards.

Ventus OGI Camera Models

Sierra-Olympia’s line of gas detection cameras are called Ventus, the latin origin of the word wind. All of the product names that we use in our company are oriented around the the word wind, because in Hood River, Oregon is known for kiteboarding and windsurfing. Our camera technology uses hot mid-wave infrared detectors. HOT stands for high operating temperature. For many years the mid-wave cooled infrared cameras were based on a material called indium antimonide or mercad telluride. Materials had to be cooled to cryogenic temperatures around -200° centigrade or 77° kelvin. Over the last five years, the United States defense industry helped pay for the development of new detectors. Sierra-Olympia technologies has been at the forefront of being able to implement these detectors into our cameras. The high operating temperature means that the sensor is operating at about 150° Kelvin versus 77° Kelvin or about -100°C vs. -200°C. The new integrated dewar cooler assemblies are much smaller, require less power and are lighter weight. This huge technological jump allows us to develop for drone or UAV crewed and uncrewed OGI systems. We are also excited to develop for the handheld portable products. We have been shrinking the technology over 20 years.

Increasing VGA Resolution

With the Ventus line we introduced a VGA resolution sensor, 640 x 512. The industry was at quarter VGA, 320 x 240 resolution. We were able to increase the resolution and get four times the number of pixels. The goal is to be able to see smaller leaks at further distances. What we see coming in the future is going to be HD, 1280 x 1024 sensors to detect and visualize even smaller leaks at greater distances.

Long and Continuous Operating Cooler Hours

HOT sensors coolers that we use have also improved. The limited life and operating hours were generally rated for 8k – 10k hours. Today’s HOT mid-wave sensors have increased to 16k – 20k hours. Some of our newest cameras are employing coolers that are going to last about 36k hours. This is super important as we look at fixed mounted and continuous monitoring. One of the biggest concerns in any industry is having to service a product on a frequent basis. We are trying to get in front of that so when you install these types of systems in a permanent application monitoring 24 hours a day, seven days a week, 365 days a year, you’ll be able to run for 4 – 5 years without having to do any maintenance. This type of technology enables us to be able to achieve those goals.

Detectable Gasses

Inside of the OGI cameras is a narrow band pass cold filter. The mid wave infrared region where all of alkane and hydrocarbon gasses are detectable is typically 3 – 5 microns. We put a cold filter inside of the dewar cold section of the camera and it’s a narrow band to about 3.2 – 3.4 microns. The deltaT that was mentioned earlier helps you better visualize a warmer or a colder background. Typically our cameras are able to discern that down to much lower temperature deltaT than the 5° that’s being specified in OOOb. We’re generally down to a 1°, 2° centigrade deltaT. Our cameras have many image processing algorithms that help enhance the image so we are able to reach out and see smaller leaks at further distances.

| Ethane | Propane | Propylene | Methane |

| 1-Pentene | Butane | Ethyl Benzene | Heptane |

| Hexane | Isoprene | Octane |

Our OGI Applications

Some applications for OGI cameras you’re probably fairly familiar with, but maybe some of them are not. All of our products or cameras are considered components. What we do is we enable technology partners to create finished solutions. Everything that we have in a trade show booth is an open frame configuration with the electronics exposed. Our customers take our products and integrate it into something that becomes a finished good.

Large Area Surveillance OGI

AURA OGI™ is a new product through a company called Champion X. They are located here in the Houston area. Many of you may know of Champion X as a petrochemical chemical type company. They’ve been around for over 100 years and recently doubled down on emissions by creating a whole business unit around it. They understand OGI technology, really one of the leaders right now. What’s unique about this their product is it was designed specifically to meet OOOOb, OOOOc and Appendix K, and the camera has a positioning and navigational system.

The camera features a state-of-the-art navigational and positioning system that allows a user to upload a Leak Detection and Repair (LDAR) route with the specific assets in the facility that need to be inspected. Each asset then has a specific geotagged location. When the operator takes the camera and holds it up to their eye, within the viewfinder they will see a series location pins on every asset in the field of view that needs to be scanned. The pins are white, meaning they need to be scanned for an allotted amount of time, typically between 5 – 10 seconds. Once the asset has been scanned the location pin turns to green indicating it has been scanned. With this procedure, it means the OGI inspection provides traceability that the person using the camera looked at and scanned the pieces of equipment on the route. If there is a leak, a caution or critical note can be added with text or audio. The camera can record the Delta Temperature Measurement . It has a laser range finder built in and a visible light daytime color camera. The camera will have quantification capability. There will be two models available, one with ATEX and Class 1, Div. 2, EX-rating and one without the EX-rating. There is also an Class 1, Div. EX-rated Wi-fi/Blue Tooth tablet available for viewing exactly what the operator is seeing in the view finder, so an experienced OGI operator can train a new operator.

There’s another company called MFE Inspection Solutions. They’ve done a different type of integration where they use SPOT from Boston Dynamics.They have the OGI camera integrated on SPOT with a microphone that allows them to be able to listen for the leak as the camera visualizes. You know exactly where the point source of the leak is and doing autonomous routes using SPOT’s mobile capability. The camera is removable from the drone turning it into a handheld unit. An Android smartphone app is used to control it and it’s got a long life battery that lasts about 4 hours.

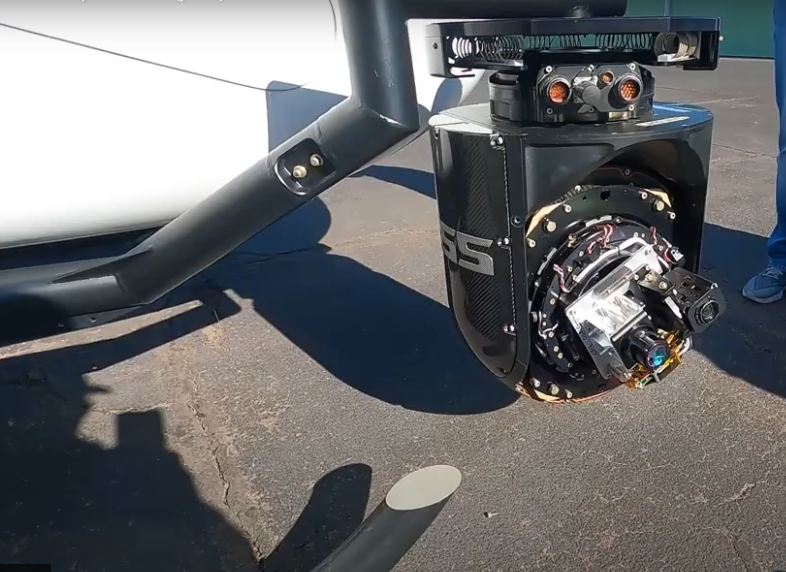

Uncrewed Drones OGI

Many people are familiar with drone platforms. Our product is integrated on many different ones. One such company called Free Fly which manufactures a drone called Astro for field inspections. Recently Sony has decided to jump into the business of OGI inspection with a product called the Air Peak. They have integrated the Ventus OGI camera core onto their platform with a visible light camera and an optional TDLAS laser.

Other drone manufacturers who integrate the Ventus OGI camera core include: Percepto, based out of Israel, and with significant operations in the United States, offers a drone-in-the-box solution. Another drone technology partner, based in the UK is a company called Evolve Dynamics.

Lastly, probably the most used drone in the world for industrial inspections, the DJI M300 and the previous model, the M210 uses the Ventus OGI camera core. Coming up in the future with the introduction of their new M350, you’ll see the Ventus OGI camera integrated onto this aerial platform. Here the Ventus OGI can be combined with TDLAS and sniffers for quantification, or in some cases, people are also working on doing quantification optically and not using a 3rd party sensor, but using just the image itself to do quantification.

Gas Enhancement Mode

We developed the gas enhancement mode that colorizes the gas plume, makes it easier for the human eye to be able to a certain of where the leak is coming from. The sharpness and clarity of the image is really significant. We are able to find these kinds of emissions a lot easier and faster.

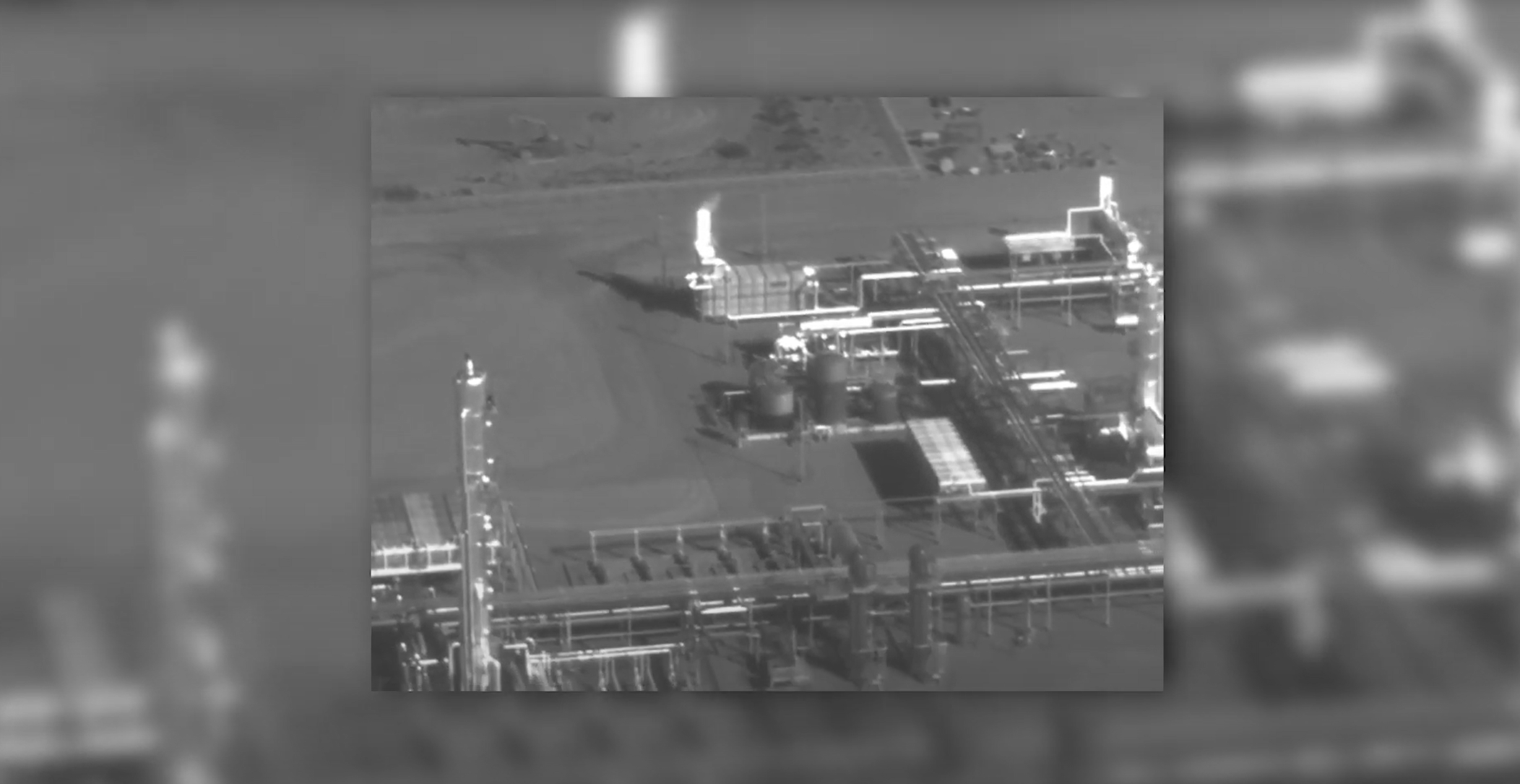

Crewed OGI

Our cameras are used in crewed systems as well. One of the most mature integrations is into stabilized gimbals on helicopters and fixed wing aircraft. This is a very viable way to do very significantly large areas or linear assets like pipelines. When incorporated with overlays of the the OGI on to the visible light and laser range finders that precisely indicate exactly where the leak is and at what distance it is. Again for traditional pipeline patrols that people are doing for right away inspections, we have companies that are integrating Ventus OGI cameras on to like Cessna aircrafts and then larger aircraft to come as we get waivers for beyond line of sight.

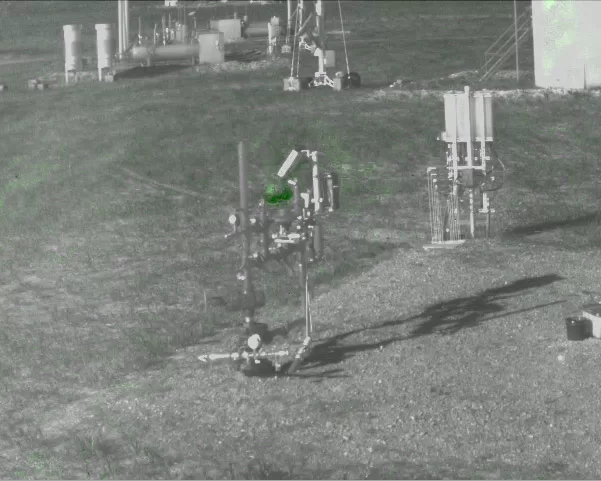

Fixed Mounted Continuous Monitoring OGI

Last is fixed mounted continuous monitoring applications. Permanently mounted technology requires a long life cooler to improve reliability. The state of Colorado is setting new standards as far as and new well pad, as soon as you dig into the ground, you have to start monitoring it too. When the well comes in through its completion process, and six months after, you have to monitor the site 24 hours a day, seven days a week, 365 days a year. This is not possible with any other technology except fixed mounted. We’re working on new technology to to help lower cost and increase the reliability.