Machine vision for detection and recognition can greatly expand any equipments field of applications. Determine predictive maintenance, level of threat or enable quality control.

Robots have become more capable of preforming highly complex tasks through the use of thermal imaging. Detection and recognition require a clear image to to see the warning signs such as temperature, or a small pixel count that recognizes subtle differences and anomalies. The results of using a thermal camera for machine vision have been known to maximize production lines and reduce costs.

Machines applications are expanding in all directions and our thermal systems support modern connectors.

Many of our cameras support GigE or USB 3 connectivity, helping to make them compatible with the modern machinery. We can help with custom OEM integration and synchronizing outputs or controls for machine performance, data collection or other IIoT applications.

Industry Applications

Vision to Guide and Detect

Gain more sight in environments where vision is limited. Guide your drone through obstacles and the unforeseen with the use of infrared.

Production Line Monitoring

Use thermal technology in your production line to carry out specialized tasks rapidly. Detect and sort based on quality using IR vision.

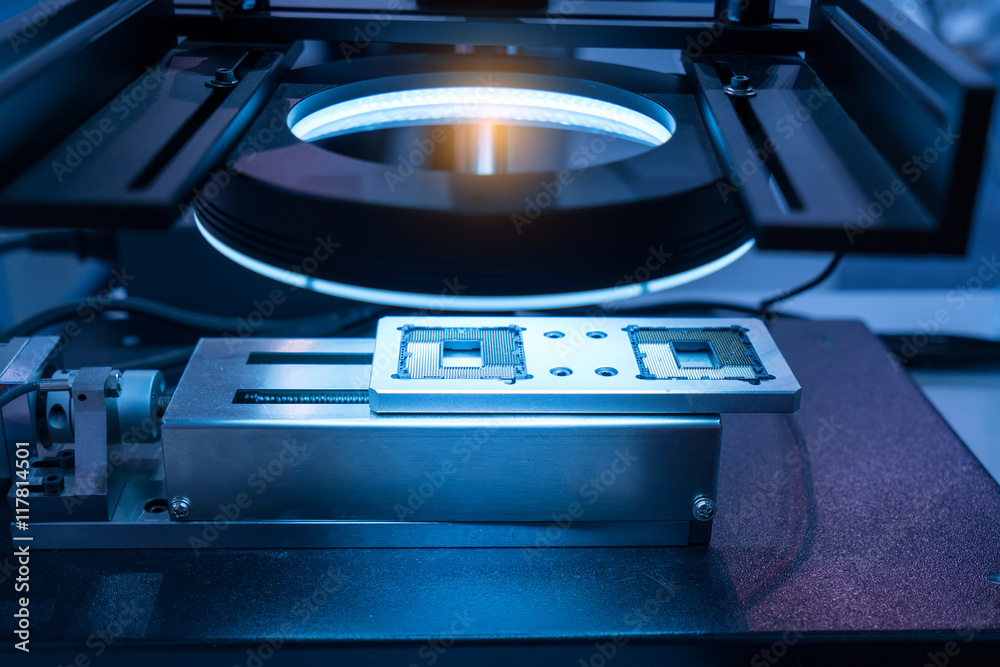

Surface Inspection Methods

Collect heat resistance data or early corrosion characterization. Measure for your best operating temperatures and environments.